Digital Port Operations for Greater Efficiency

About the Customer

Our customer is one of the largest companies in South America specializing in efficient port operations and integrated logistics. Their container terminals across the continent manage loading and unloading of commercial and industrial ships, warehousing and ancillary services. This port leader is responsible for 18% of all container and cargo movements in Brazil and offers complete solutions from port to e-commerce. Our customer plays a critical role in global trade, serving as a vital hub for transferring cargo between ships and land-based transport systems.

Project Summary

Ship-to-shore (STS) cranes are essential equipment to the customer’s operations, enabling the seamless transfer of containers between ships and the port yard and forming the backbone of their logistics chain. Additionally, rubber-tired gantries (RTGs) are indispensable for safely stacking and organizing containers within the yard, ensuring optimal use of space and smooth workflow. Engineering Industries eXcellence digitalized the customer’s critical machinery to enhance operational efficiency, decision-making and sustainability.

Project Activities

- Defined a scalable, secure and robust architecture to meet project objectives and support future expansions.

- Established connectivity with Siemens PLCs to extract real-time operational data from STS cranes and a RTG, ensuring accuracy and reliability.

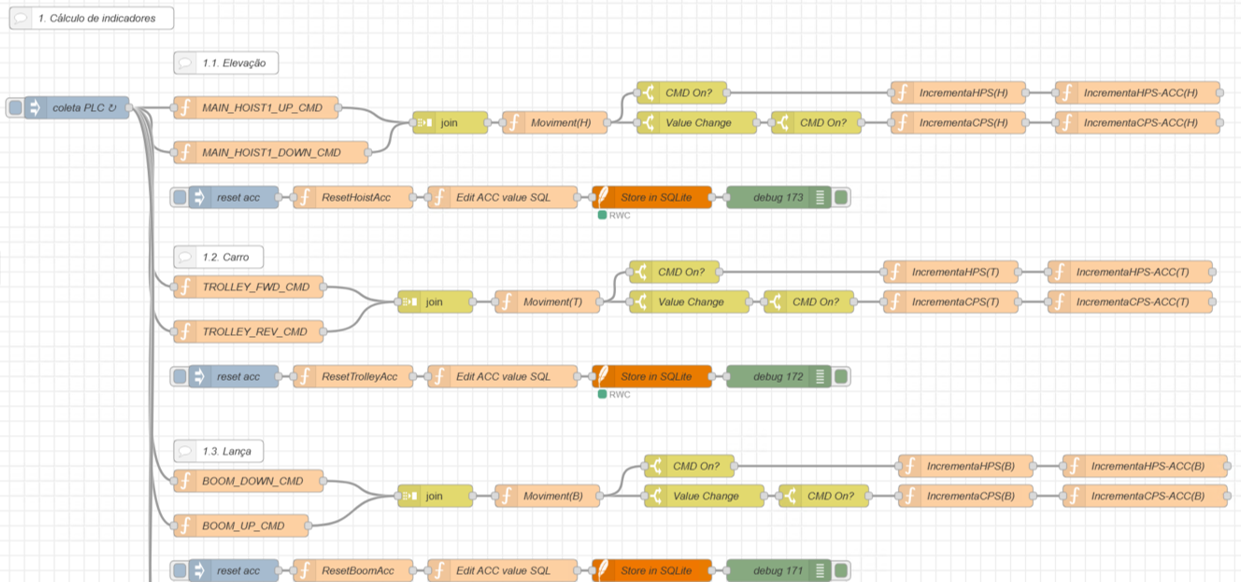

- Developed advanced algorithms to calculate key performance metrics for energy consumption, predictive maintenance, and operational performance.

- Configured VPN routes, firewalls and secure communication protocols to enable safe and efficient data transfer between the customer’s environment and Google Cloud.

- Leveraged Google Cloud’s BigQuery and Pub/Sub services for scalable, secure storage and efficient management of raw and processed data.

- Designed an intuitive, cloud-based dashboard using Looker to provide stakeholders with actionable insights through visualized KPIs and raw data.

- Conducted a successful pilot deployment on the first STS crane, incorporating customer feedback to refine and optimize the solution for broader application.

Business Drivers

- Enable data-driven decision-making and improve overall efficiency through clear and comprehensive visibility into crane operations.

- Identify operational inefficiencies, minimize unplanned downtimes and streamline maintenance processes to reduce costs effectively.

- Prioritize energy consumption monitoring and optimization to align with the customer’s environmental and sustainability goals, contributing to a greener operational model.

- Equip the customer with cutting-edge digital tools to maintain a competitive edge and reinforce their leadership position in the port logistics industry.

- Ensure that operational data and insights are accessible to all relevant stakeholders, fostering collaboration and informed decision-making across the organization.

More About the Project

The solution involves collecting data from cranes equipped with Siemens PLCs using the Siemens Simatic IOT2050, an Industrial Edge device. This data is processed into meaningful Key Performance Indicators (KPIs), including predictive maintenance metrics, strategic logistics insights, energy efficiency indicators and overall performance evaluations using Node-RED. The processed KPIs, along with raw data, are sent to the Google Cloud Platform via Pub/Sub and stored in BigQuery. These insights are accessible through a cloud-based business intelligence (BI) dashboard, developed using Looker, which enables stakeholders to monitor machine performance and make data-driven decisions.

This digitalization initiative transformed how the customer interacts with their core machinery, enabling predictive maintenance and real-time performance monitoring. The solution reduced downtime, minimized unexpected failures and increased operational productivity. By democratizing data access, the solution empowered stakeholders across the organization to collaborate more effectively and make informed decisions based on a unified view of machine performance. This transparency streamlined workflows and enhanced operational efficiency across departments. The project also aligned with the customer’s sustainability and digital transformation objectives. Leveraging a scalable cloud solution, it supports expansion to additional machinery while promoting energy efficiency. These innovations position the customer as a forward-thinking leader in the competitive port logistics industry.

Engineering’s Advantage

Engineering Industries eXcellence is a global software developer and system integration leader. Leveraging our proficiency in Google’s product suite and our extensive experience in process automation, we empowered our customer to enhance efficiency, reduce costs and achieve operational excellence at their South American port. Although the initial project scope covered just 10 STS cranes, the customer has expanded this digitalization initiative across their enterprise, demonstrating the scalability and flexibility of the solution. We will continue to bring meaningful transformation to the port leader through the rollout of this project and for many years to come.