Closed-Loop Manufacturing, Realized

Integrating ERP, PLM and MES to Achieve Smart Manufacturing

The Background

Digitalization is changing how humans live and behave in many ways. It has a huge impact on almost all aspects of society. Just look at manufacturing. Factories have used digital applications for decades, but the impact of a new technological paradigm founded on the Industrial Internet of Things (IIoT) and realized in the Industry 4.0 concept, is driving the world of manufacturing into a completely different playing field.

Enter Smart Manufacturing, where new perspectives enable production strategies to evolve in a way which drives process optimization, intelligent decision support and the continuous improvement of Products, Processes and People.

So how do we achieve this? Simple: with information and connectivity. Data is the key and integration, in the broad sense, is the tool that enables Smart Manufacturing.

Who are the players? Companies, Customers, Partners, Suppliers and Dealers must be considered the key actors in the modern supply chain, across which the generation, usage and sharing of data acts as the foundation for efficient processes and value creation.

Why integration? Integration of Digital Applications enables the effective sharing of data. An efficient way of processing and analyzing data can generate informed insights that account for every phase of the product lifecycle. With the right information, all the functions of the company become more sustainable, more efficient, more proactive and, most importantly, more capable of generating business value.

Following this integration approach, a single continuous process called Closed-Loop Manufacturing is created, and it includes business planning, product design, manufacturing planning, production execution and product delivery.

The Proposition

Keeping those concepts in mind, Engineering Group has combined the power of our Business Process Expertise, Cross-Industry Experience and In-Depth Technical Knowledge of the top industrial applications on the market to deliver a vision for Smart Manufacturing that can actually be realized today.

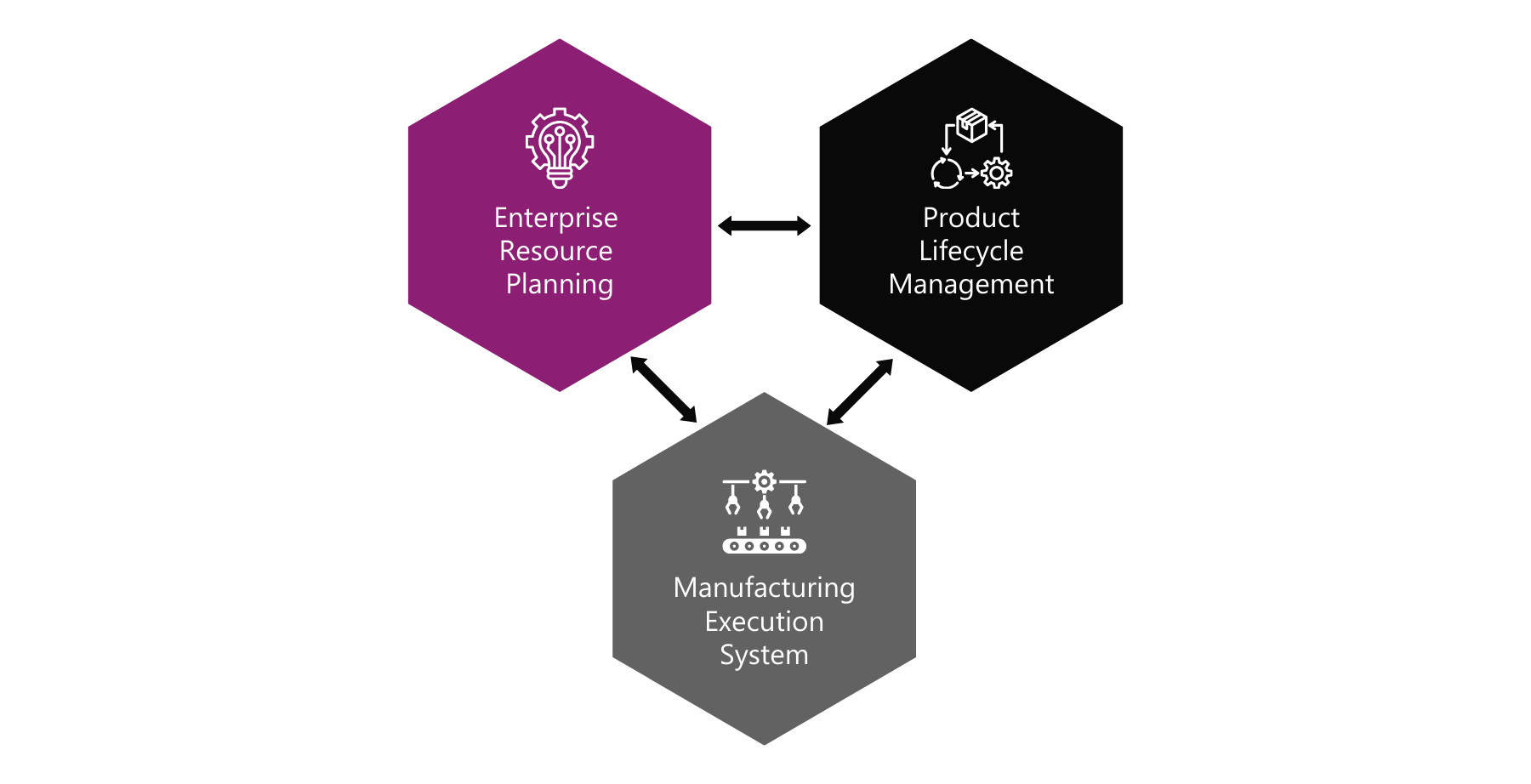

In software terms, when Product Lifecycle Management (product design and manufacturing planning), Manufacturing Execution Systems (production execution and quality control) and Enterprise Resource Planning (business planning, intelligent asset management and product delivery) get together – the sum, as it sometimes happens, becomes greater than any of its individual parts.

In integration terms, Engineering Group’s global competence centers provide the critical capabilities necessary to bridge the digital gap between business, engineering and operations. Our Engineering Industries eXcellence and Engineering Enterprise Solutions teams have the combined depth of experience and skilled resources needed to design, implement and integrate processes and technologies across PLM, MES and ERP in order to deliver an integrated approach that enables manufacturing organizations across all industry sectors worldwide to bring their Smart Manufacturing visions to fruition.

The Business Requirements

Smart Manufacturing enables sustainable and efficient production by nature. The key requirement is that, at every single stage of the production process, all the relevant information must be available, so that the right decision can be made, or the right procedure can be activated automatically. The Data that makes up this information can be generated in many places and in many different ways.

Product Designs, Production Equipment, Production Test Systems and even Produced Goods are all sources of what we call Front-End Data. This data is handled through PLM, MES and related operational applications.

At the same time, Back-End Data, which is handled through ERP and related business applications, is also a very relevant and important source of information impacting production. Examples of this data include Customer Requests, Sales Orders, Parts Availability, Maintenance Schedules, Human Resource Shift Plans and so on.

Supply Chain Data from external entities such as Partners, Suppliers and Distributors also needs to be part of the data picture since it provides parts and services necessary for the execution of both production and delivery processes. Logistical and material management information coming from product warehouses and transportation networks plays a relevant role too.

On top of that, don’t forget Market Data related to Demand, Economics/Financials, Stock Availability, Replenishment Needs, Regulatory Guidelines and much more.

When you think about it, the data pool seems overwhelming. To enable effective operations management, this vast amount of data first needs to be collected, analyzed and presented in a timely, accurate and proper way. And to enable true Smart Manufacturing, Artificial Intelligence and Machine Learning must then be applied to drive continuously more optimized, intelligent and ultimately autonomous decision-making.

The Processes Supported

Understanding and harnessing the power of data is critical to Smart Manufacturing, but it is not enough. How do the different sources of data we are looking at interact with and impact each other? We must understand this in order to create a feasible integration plan that will successfully connect all the different processes that play with manufacturing across the organization. When the loop is closed and data is available in the right form, production is efficient and quality increases.

Let’s take the Food & Beverage Manufacturing industry as one example. What are the Processes at play? What Business Groups and Departments are involved? How do they interact with Production? How does production impact them?

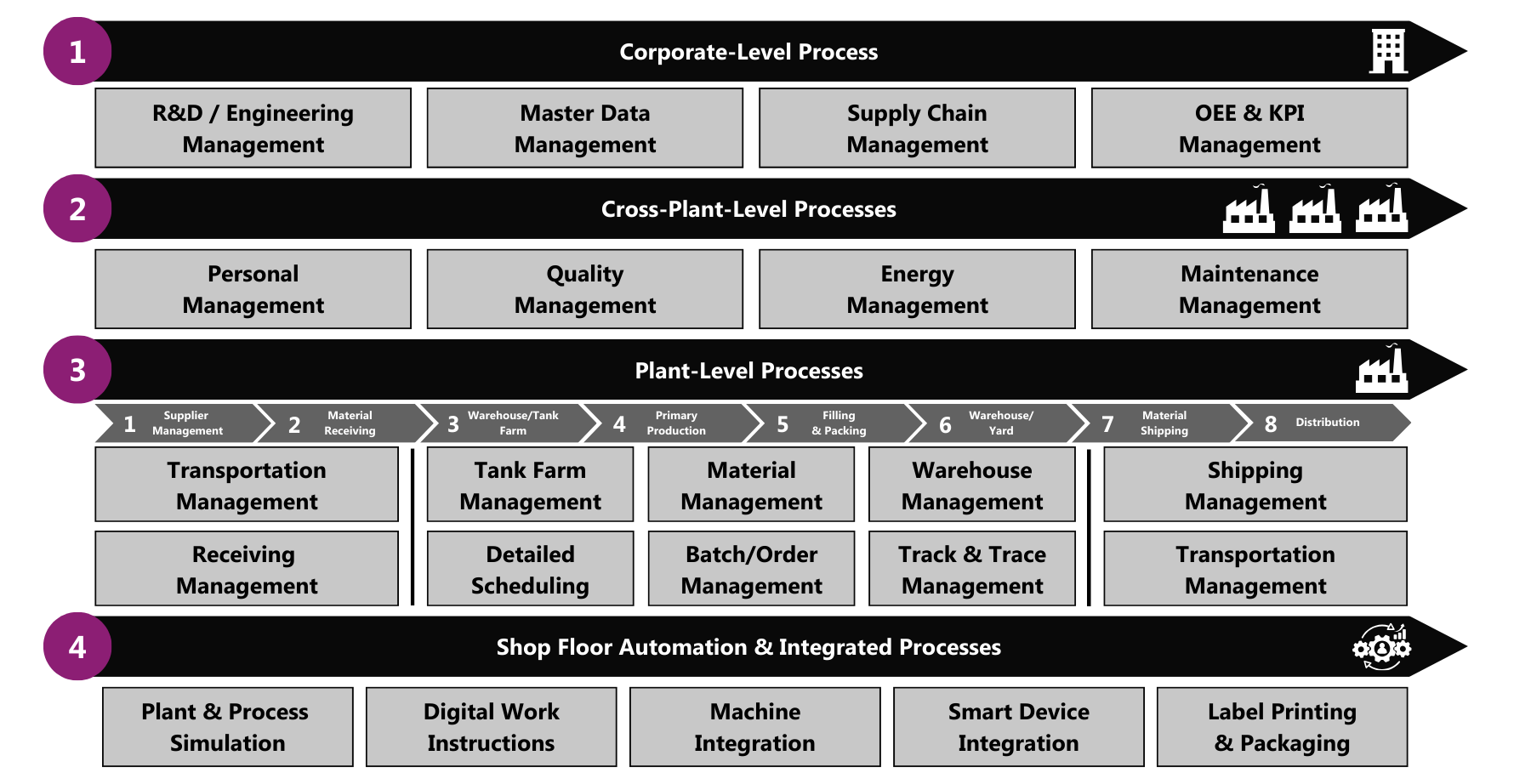

Level 1: Corporate-Level Processes

At the Corporate Level, we have a set of processes that are common across the organizational enterprise. They are vertically integrated and communicated until they reach the equipment on the factory floor.

For example, changes in product design by engineering are fed down and across the enterprise, driving changes in planning, procurement, operations and ultimately how the product is manufactured in the plant.

Level 2: Cross-Plant-Level Processes

At the Cross-Plant Level, we have a set of processes that must be managed and evaluated as a whole, across business functions and activities, usually because there is a strong need for their standardization across plants.

For example, to compare the efficiency of different sites, companies must define how to measure key performance indicators in a standardized way – in terms of OEE, throughput, resource utilization, energy consumption, etc.

Level 3: Plant-Level Processes

At the Plant Level, we have a set of processes whose high-level planning is initiated at the corporate level, then fed down through operations and finally executed at the detailed level in the individual plant.

For example, orders generated by sales to satisfy a new demand or customer request will be scheduled to be produced in a specific region, plant or line based on different constraints, requirements and priorities.

Level 4: Shop Floor Integrated Processes

The Integration of Shop Floor Assets and Processes into the Smart Manufacturing workflow enables continuous optimization and improvement of activities as they are being executed by people and machines on the factory floor.

For example, integrating smart devices for asset performance monitoring enables plant managers to oversee production in real time. As a result, they can react faster to unforeseen events and thus prevent costly interruptions.

The Technical Architecture

To enable Smart Manufacturing by means of closed-loop data workflows, the key is to realize PLM, MES and ERP integration via Bi-Directional Technical Interfaces. The three systems, once integrated, become interdependent, and the resulting technical architecture is able to support the entire product lifecycle process from start to finish:

- Product Lifecycle Management (PLM) provides data management capabilities for product design, product definition, quality planning, manufacturing process planning, product configuration and change management;

- Manufacturing Execution Systems (MES) provide operational execution capabilities for production order execution, production data collection, quality data collection, quality testing and production confirmation;

- Enterprise Resource Planning (ERP) provides high-level business capabilities for sales planning, supply chain operations, manufacturing planning, procurement, intelligent asset management and resource management across the enterprise.

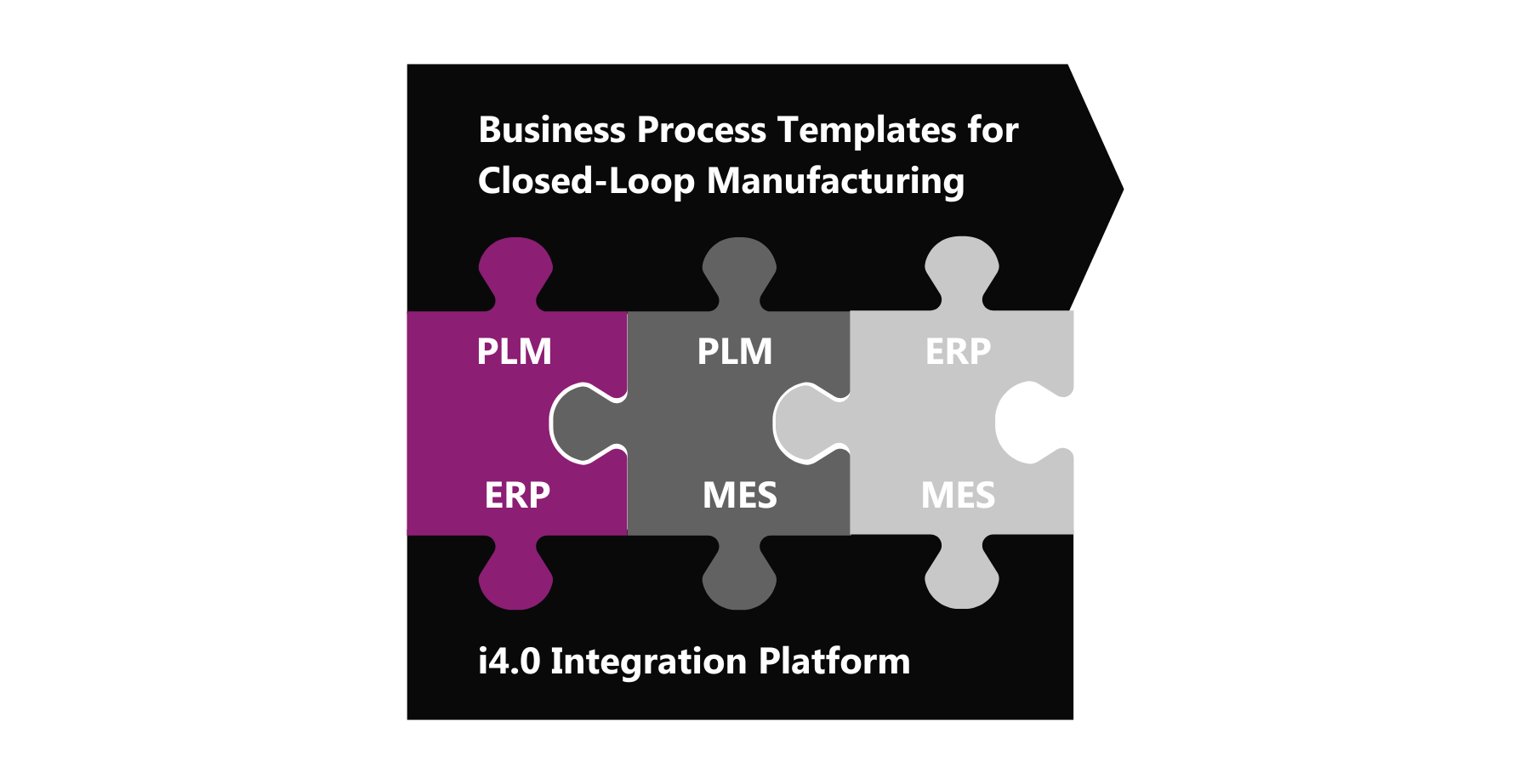

The goal of integration is to implement the Digital Thread – a seamless data flow which ensures that all the right information is available when and where it is needed. The resulting technical architecture then becomes the foundation of your organization's Business Process Templates for Closed-Loop Manufacturing.

Interface: ERP-to-PLM Integration

The first bi-directional interface implemented provides the collaborative link between PLM and ERP, thus ensuring that the system of record for product in PLM feeds the system of record for business planning in ERP. The PLM system manages product data from initial design, as it is revised and through release for production, while the ERP system uses the product truth provided by PLM to accurately plan for and manage production resources and financials. This synchronization via integration is key to driving innovative product development and profitable launch of products.

Interface: PLM-to-MES Integration

The second bi-directional interface implemented provides the collaborative link between PLM and MES, thus extending the value of a PLM system's broad data management capabilities from design and manufacturing planning to production workflow execution. This integration creates a single source of truth throughout the product lifecycle, ensuring that every order executed in the factory is done so in line with all product and process specifications. As a result, quality is controlled and assured, the risk of costly rework is eliminated and time-to-market is significantly reduced.

Interface: ERP-to-MES Integration

The third bi-directional interface implemented provides the collaborative link between ERP and MES, ensuring full alignment between the business planning and production functions of the organization. This integration enables the timely exchange of critical information between sales, procurement and supplier networks with real-time activities on the factory floor. Data shared and synchronized via integration can include the status and availability of raw materials, warehouses, product inventories, people, assets, equipment and data.

Connection: i4.0 Integration Platform

All three bi-directional technical interfaces are connected to the i4.0 Integration Platform, a centralized cloud-based hub providing all the services required to realize and manage the multi-system interconnections and interfaces. The flexible platform is designed and built in a way that gives manufacturing organizations the option to extend its capabilities to and from other enterprise systems or applications if and when desired.

Designing The Solution

Digital transformation means using technology to create new (or modify existing) business processes and adapt to changing market demands. An effective digitalization strategy begins with an in-depth assessment of a company's "as-is" processes, the results of which then drive the design of a holistic "to-be" solution capable of satisfying all functional and business needs.

What: Process Mapping & Templates

To help industrial companies control and integrate all information flows that play with manufacturing, we have established a proven set of Industry-Specific Templates and Best Practice Methodologies. These are used to document processes, both manual and automated, across different departments of the enterprise in order to create a visual map of how they interact with each other and with factory operations. Using this roadmap, we can ensure that no process is left behind in the design of the final solution.

Who: Role-Based Application Design

The Role of People must also be considered and built into a digitalization strategy from the start. How can we ensure that we deliver value focused on users? How can we ensure that the digital infrastructure is built in a way that supports people and their continuous improvement? We do this by collecting user requirements at the start and by collaborating with them and other stakeholders throughout the development process.

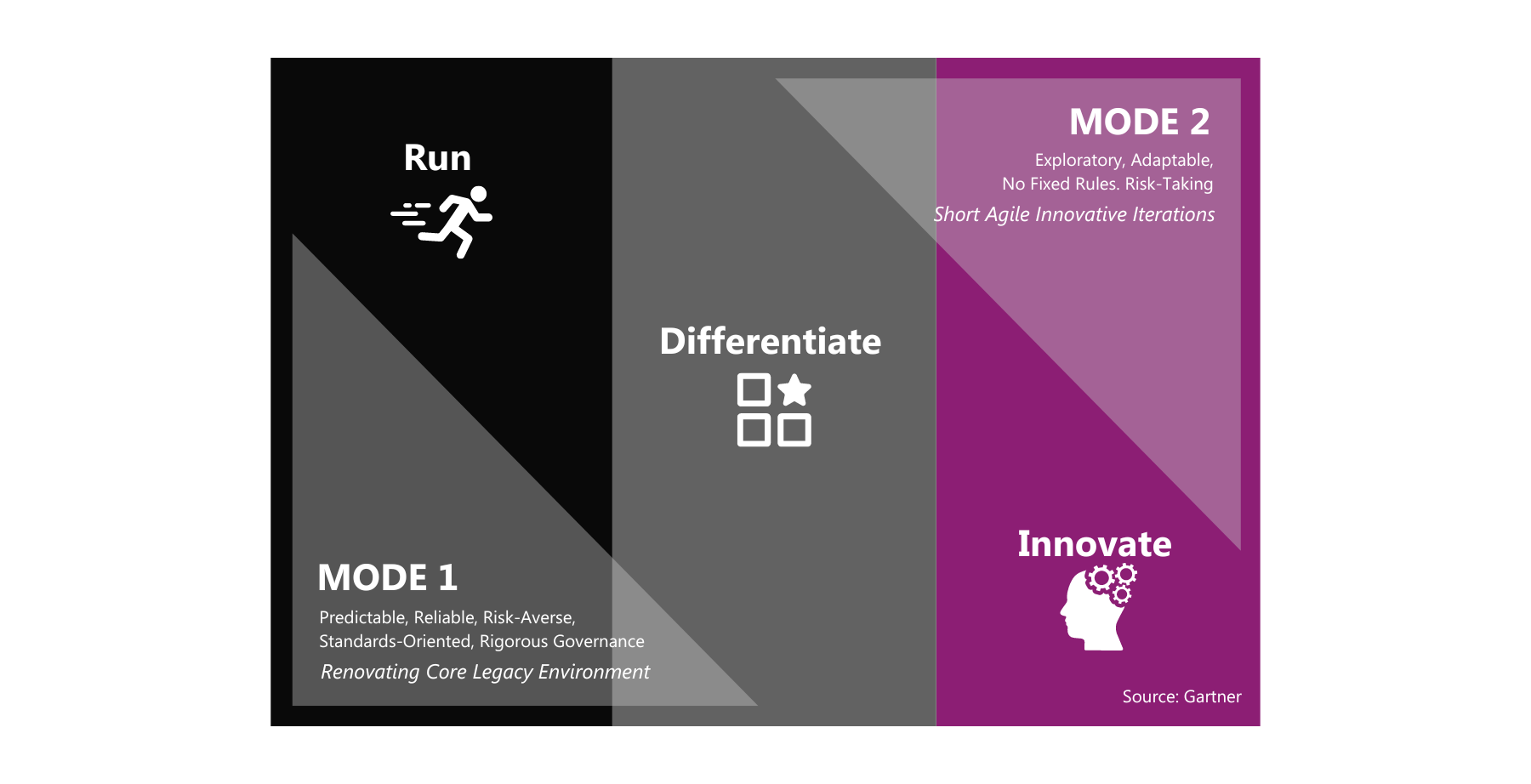

How: Bimodal Digitalization Approach

Our industry-specific business process templates were built aiming to marry a more predictable evolution of standard products and technologies together with the newest, most innovative approaches to digitalization. This is the essence of what Gartner has called the two-speed Bimodal Digitalization Approach.

When implemented correctly, this approach to solution design promises the fastest and most effective path to Smart Manufacturing for industrial organizations across all sectors. The two-speed approach states that an organization’s Industry 4.0 roadmap should consider and include two separate (but simultaneously occurring and complementary) solution architectures:

- Mode 1 focused on PREDICTABILITY and RELIABILITY (e.g., core systems such as ERP, PLM, MES, QMS, etc.);

- Mode 2 focused on AGILITY and EXPLORATION (e.g., enabling technologies – Cloud, Low Code, AI, etc.).

Building The Solution

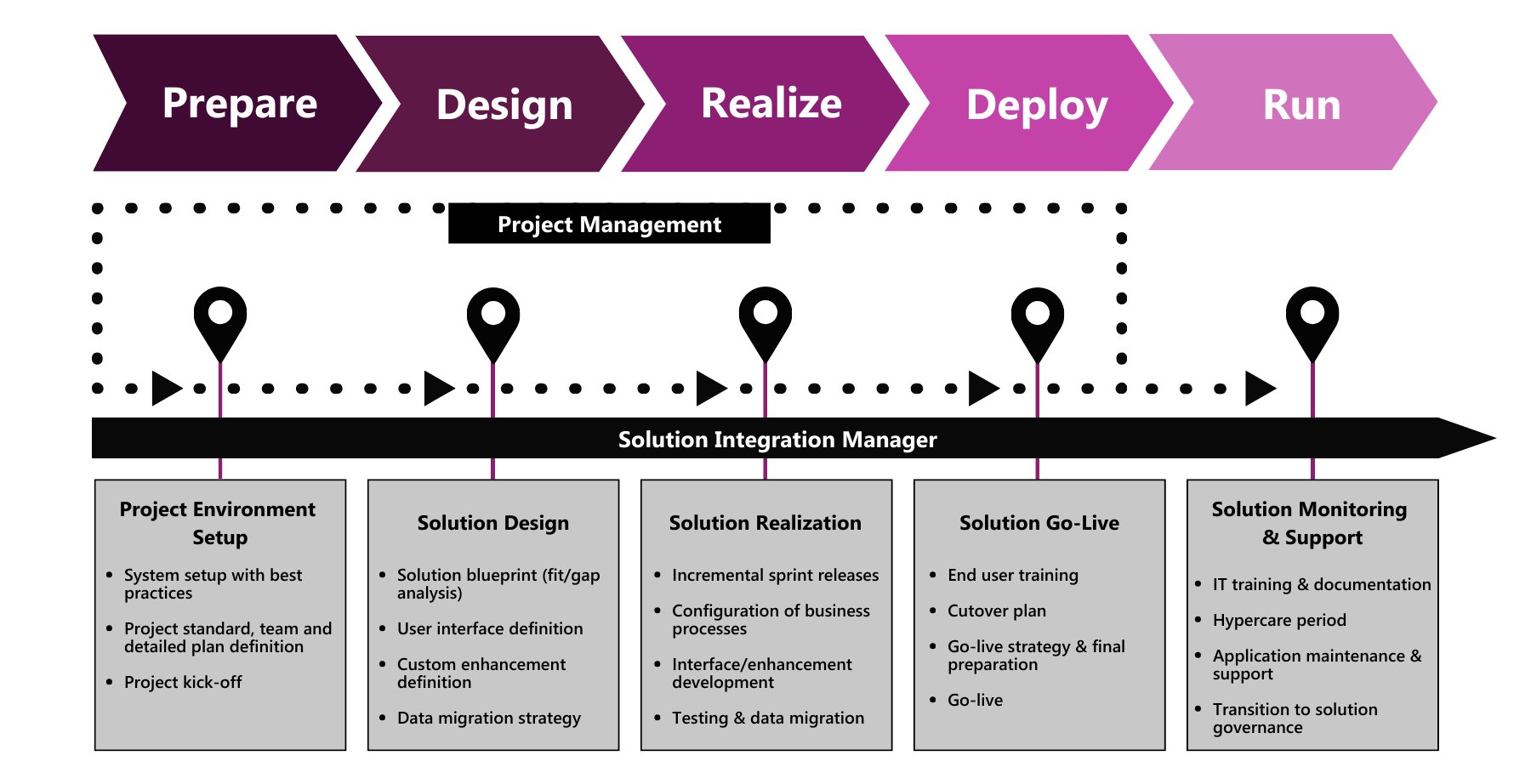

Each segment of the solution blueprint designed is developed and validated following our organization's proprietary software implementation methodology: ENGILE.

ENGILE combines an innovative agile approach with specific items from the traditional waterfall methodology for software development. As a result, we are not only able to deliver integrated Closed-Loop Manufacturing solutions faster and more cost-effectively than any other system integrator in the world, but at the highest quality too.

The ENGILE approach is proven to minimize risks, increase control and achieve project goals on time and as expected.

Delivering The Project

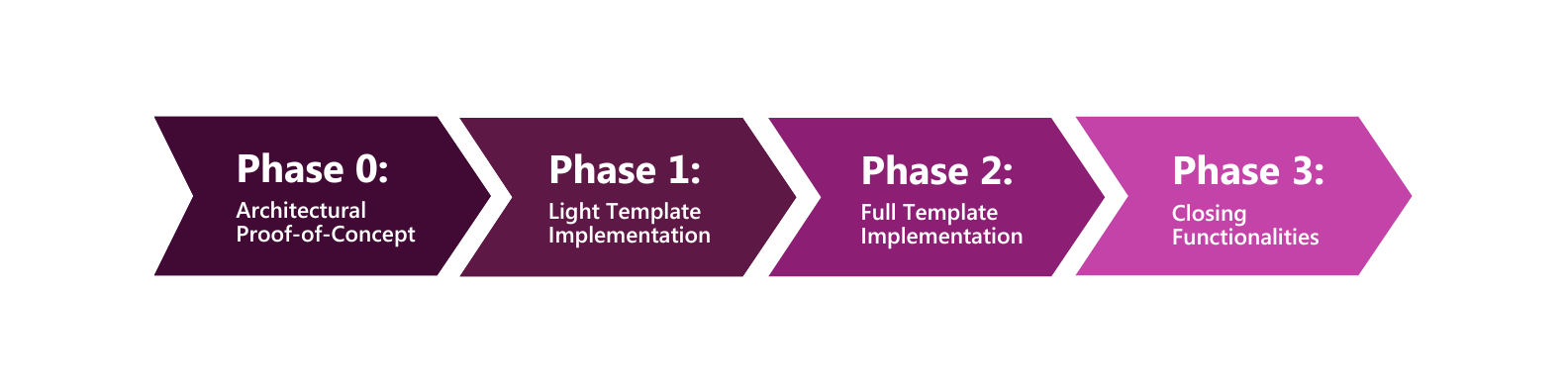

Our typical approach for the successful delivery of a Closed-Loop Manufacturing Project starts with a pilot or proof-of-concept, followed by three implementation phases:

Phase 0: Proof-of-Concept

The Proof-of-Concept aims to prove out selected functions and capabilities of the final solution in a selected plant or production line in order to ensure solution viability without risking disruption to plant or business operations. This is also the starting point for the design of the i4.0 Integration Platform environment in the cloud, considering connectivity with the bi-directional technical interfaces to be established in the next phase.

Phase 1: Light Template Implementation

The Light Template Implementation aims to extend the proof-of-concept to cover a greater number of plants and/or production lines. It also includes the implementation of the first version of the integration architecture, establishing connection between bi-directional interfaces and the i4.0 Integration Platform and validating critical data collection and management functionalities.

Phase 2: Full Template Implementation

The Full Template Implementation releases all of the remaining functionalities of the integrated ERP to PLM to MES solution as designed. This phase includes activities that customize the capabilities of the i4.0 Integration Platform in the cloud. Local servers, all integrated with the platform, can also be installed to enable greater on-site control.

Phase 3: Closing Functionalities

The Closing Functionalities phase aims to complete the realization of Closed-Loop Manufacturing by extending the integrated workflow to support organization-specific needs. This includes customizations and integration to other applications, such as systems that manage Research & Development or Supply Chain (shipping and receiving) processes.

Our Technology Partners

We believe that innovation separates industry leaders from laggards. Continually increasing demands for end-to-end integrations also require tight collaboration across Technology Partnerships. Our network of global partners gives us access to the most cutting-edge technology on the market. These alliances, such as SAP and Siemens, enable us to weave complex data flows across solutions in order to fabricate complete product lifecycle digital threads. As a result, we can offer right-fit solutions for our customers that help ensure the success of their digital transformation initiatives.

Why Engineering Group

The number of systems that are utilized to streamline and control the manufacturing process grows exponentially as technology progresses. Manufacturers rely on these systems to bring their products to consumers efficiently and profitably. These systems are not just nice to have; they are required in today's highly competitive market. To utilize them to their full potential, these systems need to communicate and operate in a unified way. In order to accomplish this integration, broad expertise from the top of the stack to the bottom, in-depth knowledge of industrial processes as well as proven implementation success are required. Engineering Group is one of the few companies in the world that has both the vision and the skillsets needed to not only speak about Smart Manufacturing, but to make it a reality for industrial organizations worldwide.